AquaTex™ TFC system receives process wastewater from the facility by gravity drains throughout

the plant that feed to the Wet Well Tank (T-1000). Lead-lag controlled S.S. Submersible Shedder

Wet Well Pumps (P-1100/1200) located within the Wet Well tank transfers the incoming water at a

maximum flow rate of 1,500 gpm to the 25,000-gallon Wastewater Collection Tank (T-2000).

The underground Wet Well Tank T-1000 collects all process wastewater directed to the AquaTex™ TFC system.

There are two non-clog shedder Wet Well Pumps installed (1-Duty, 1-Standby) providing for redundancy. The Wet Well Pumps transfer the incoming water from the Wet Well (T-1000) to the Wastewater Storage Tank (T-2000). The PLC program will automatically start and stop the pumps as required. Each pump is equipped with soft starters and are mounted on a slide rail system for easy removal.

The 25,000 Wastewater Storage Tank (T-2000) provides equalization storage while the AquaTex™ TFC system continues to discharge at a lower rate (operator controlled), normally 150-250 gpm.

The variable system flow feed rate (100-450 gpm) equals the system discharge rate and is set by the operator using the HMI controls. The set flow rate is controlled using a flow meter (FIT- 2300) and a flow control valve (FCV-2300).

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

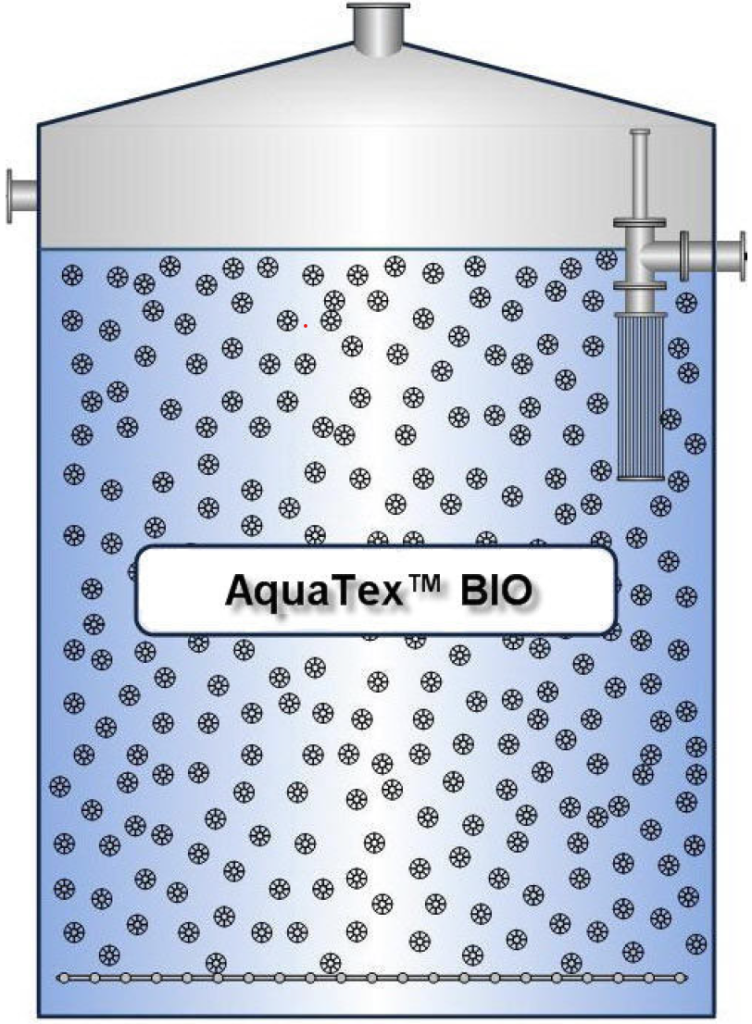

Offering eco-friendly wastewater reclamation and treatment systems since 1988. AquaTex™ BIO & AquaTex™ TFC.

© 1988 - 2024 Wastewater Resources Inc. All Rights Reserved.