Wastewater Resources Inc. (WRI) manufactures five advanced water purification plants for the industrial process water market: AquaTexäð COG, AquaTex™ HS, AquaTex™ SBR, AquaTex™ LLD and AquaTex™ CT. To service its industrial and commercial clients, WRI offers AquaTex™ CT to reclaim, clean and recycle cooling tower water.

AquaTex™ CT (Download PDF)

Business Case - The first AquaTex™ CT was designed to treat cooling tower "blowdown" water for virtually any commercial-grade cooling tower. The first AquaTex™ CT was designed and installed in the late 1980's. A patent was received for its recycling and advanced oxidation processes, coupled with nanofiltration to continually filter, disinfect, and recycle blowdown water. Its simple reclamation design reduces tap water and sewer charges by 60% to 80%. AquaTex™ CT is typically custom engineered to accommodate a specific footprint, the content of blowdown water and the brand of cooling tower.

|

|

Technology - AquaTex™ CT uses a sophisticated prefiltration process consisting of tubular backwash filtration and nanofiltration. This multiple-stage prefiltration system removes suspended solids down to the five (5) micron level but active treatment chemicals remain in the cleaned wastewater stream. After passing through nano membranes, 85% of the total dissolved solids (TDS) and 95% of the hardness are removed. In addition, 98% of the dissolved organics and 65% of the salts are removed.

|

|

"Cooling Water: Water circulated through a cooling system to remove heat from certain areas."

"Blowdown: Water discharged from the system to control concentration of salts or other impurities in the circulating water." (Cooling Technology Institute, 2009)

|

Reclaimed cooling water then becomes a recycled water source, and 80% or more of the total blowdown is recovered for continuous use in the cooling tower. The invention replaces traditional antiscalant chemical treatments and periodic discharges of untreated blowdown water into sewer systems. Rather, the invention's unique three-stage filtration technology with a reverse osmosis element reduces the TDS content to acceptable levels and then continually recycles treated water back into the cooling tower.

|

| Benefits - Benefits derived from an AquaTex™ CT are numerous: |

- Captures, cleans and recycles up to 80% of the blowdown water

- Removes TDS and hardness but retains active treatment chemicals

- Low operations and maintenance costs

- Reduces tap water charges from municipal sources

- Reduces municipal sewer charges

- Eliminates regulatory fines for disposal of untreated wastewater and

- Reduces environmental degradation by untreated wastewater.

|

|

According to the Building Owners and Managers Association (BOMA), commercial office buildings alone use one-sixth of the world's freshwater supply and 26% of the water used in a commercial office building is consumed by cooling towers.

|

| Automated Controls - Every automated system that WRI manufactures comes equipped with a state-of-the-art control panel with the latest Allen Bradley PLC technology that offers user-friendly color touch screen programming, computer monitoring, and full reach-back capabilities to the corporate office. Whether wastewater streams are from gas wells, manufacturing plants, or cruise ships, WRI leads the industry in system automation technologies. At its manufacturing facility in Scottsdale, the Systems Automation Group builds control panels, installs wiring and electronic components, writes custom software, and prepares operating and training manuals for its clients. |

Automated Control Panel |

|

|

|

|

|

|

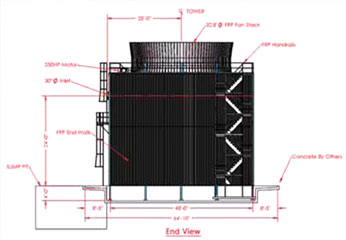

AquaTex™ CT (Cooling Tower) is designed for reclaiming, treating & recycling cooling water.

|

|

|

AquaTex™ CT (Cooling Tower)

|

|

|

| AquaTex™ CT uses sophisticated prefiltration that removes 85% of total dissolved solids but active treatment chemicals remain in the treated blowdown. |

|

|

| AquaTex™ CT reclaims, cleans & recycles 80% of the blowdown so it becomes its own water source. |

|

|

| AquaTex™ CT reduces water & sewer charges by 60% to 80%. |

|

|

|

|

|

WRI leads the industry in system automation technology. |

|

|