Wastewater Resources Inc. (WRI) is a leading original equipment manufacturer of automated wastewater treatment technologies for the Minerals and Mining Market, specializing in wastewater treatment plants for the Coal, Oil & Gas (COG) Industry. We offer two proprietary lines of scalable wastewater treatment plants to upstream producers: AquaTex™ COG and AquaTex™ COG Advanced. Our primary and advanced treatment plants can be delivered on mobile or fixed-based platforms and can be purchased or deployed under water service agreements. All of our wastewater treatment plants are:

|

scalable

|

|

Influent Capacities:

|

|

1,000 bbl / day

|

|

3,500 bbl / day

|

|

7,500 bbl / day

|

|

15,000 bbl / day

|

|

|

rugged

|

|

reliable

|

|

versatile and

|

|

automated

|

AquaTex™ COG (Coal, Oil & Gas)

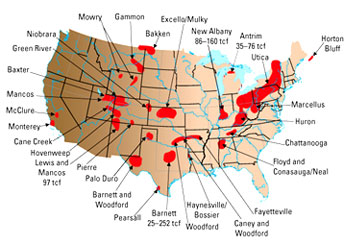

We offer AquaTex™ COG for deployment to oil and gas fields to reclaim, pretreat, and recycle well wastewaters (i.e. drilling fluids, frac flowback, and produced water). It can be deployed as a rugged mobile pretreatment plant, installed as a central pretreatment plant, or integrated as a pretreatment device on the front end of our advanced wastewater treatment plant.

Our robust pretreatment train removes suspended solids (TSS) from well and mine wastewaters. Prior to recycling treated wastewater, AquaTex™ COG's proprietary flocculation/separation/clarification process removes unwanted TSS in a single enclosed ISO-rated tank. It pretreats all wastewaters prior to additional frac stages to significantly reduce water management costs or prior deep well injection to extend the life of the injection well. As a versatile, scalable pretreatment train, it also pretreats acid mine drainage and other mining wastewaters.

|

AquaTex™ COG Advanced

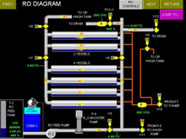

AquaTex™ COG Advanced integrates advanced treatment technology with our pretreatment train to remove both TSS and TDS (total dissolved solids) from well and mine wastewaters. It reclaims, treats, and recycles wastewater or distributes treated wastewater for beneficial uses. Our advanced product line is deployable to oil and gas fields or remote mining operations as mobile or as central treatment plants. Its unique pretreatment process removes TSS and its multi-stage filtration process removes TDS to regulatory standards or producer specifications. Treated wastewater may be recycled onsite, deep well injected, surface discharged or reused beneficial purposes.

|

Automation Features - Every automated wastewater treatment plant engineered for the upstream and mining industries comes equipped with a state-of-the-art computerized control panel with the latest Siemens PLC technologies, a user-friendly color touch screen for onsite system monitoring and management, and Internet connectivity with full reach-back capabilities to the corporate office for remote system monitoring and management.

|

Water Treatment Costs - Direct management costs, those related to water acquisition, transport, treatment, and disposal, can range from $3.00 to $10.00/bbl. Water consumption at each new horizontal gas well averages 4 million gallons or 95,000 barrels. If direct management costs average $8.00/bbl to frac a gas well, total water management costs are $750,000 or more. When the average cost to drill a horizontal well is $4 million, the total water management costs can exceed 19% of drilling and completion costs.

Deploying AquaTex™ COG and COG Advanced can reduce total water management costs by 40% or more over the lifecycle of a gas field or copper mine. If 100 new wells are being drilled in a new natural gas field, treating and recycling well wastewaters could save a producer millions of dollars compared to the traditional offsite hauling/disposal model. The real water management costs begin when wastewaters leave the field.

Variables impacting cost reductions include:

|

wastewater quality and volume

|

|

treatment specifications

|

|

freshwater acquisition costs

|

|

water and wastewater hauling costs and

|

|

waste disposal costs.

|

|

NEW WRI OFFERINGS

Lifecycle Water Management Services

(Download Scope of Services Brief)

Wastewater Resources Inc. and Black & Veatch have teamed up to launch Lifecycle Water Management Services to upstream oil & gas producers and mining operations. From assessing local water resources to site improvements to recycling treated wastewater, we offer a full suite of water management services over the life of oil, natural gas, and coalbed methane fields, as well as mining operations.

Turnkey Services - Our team relieves producers of the complex and risky job of managing water and wastewater. We specialize in water planning, permitting, acquisition, and hauling, and wastewater collection, treatment, distribution, and reporting. Our full suite of services provides a turnkey solution for managing water and wastewater in an increasingly regulated environment:

|

Water impact studies

|

|

Site design & construction

|

|

Facilities design & construction

|

|

Water procurement & hauling

|

|

Treatment technology selection & installation and

|

|

System integration, operation & maintenance.

|

Business Case - By integrating water management activities under one water service agreement, we can increase your returns on investment and reduce your risks through a 100% Water Recycle/Reuse Model. Our 100% recycle model distributes wastewater treatment in oil and gas fields to reduce water acquisition, storage and hauling costs. By contracting with us, you pay one supplier, reduce your risks, and improve your public image, while reducing costs of water management over the life of oil, natural gas, and CBM fields.

|

|

Distributed Treatment Technology - A significant component of the overall water management strategy is the locating automated wastewater treatment technology in the field or at the mine. The selection of effective treatment technology is based on water quality and volume generated in the field, as well as the end use of treated wastewater and associated regulatory standards. We ensure permitting of wastewater treatment technology, and then deploy mobile pretreatment plants to water storage tanks or impoundments and strategically erect central wastewater treatment plants in the field or at mines as needed.

Our team builds and operates wastewater pretreatment plants (coagulation, flocculation and clarification solutions) to reduce total suspended solids (TSS), advanced wastewater treatment plants (filtration and thermal solutions) to reduce total dissolved solids (TDS), and post-treatment technology (ultraviolet and ozone) to polish treated wastewater and/or to reduce salts (brine concentrators and crystallizers) prior to reuse or disposal. We also provide the process equipment (pumping, screening, chemical and material handling) that supports the water treatment plants. |

System Integration & Operation - Under a water service agreement, we integrate and operate the wastewater pretreatment, advanced treatment and post-treatment plants. We also oversee the process equipment, chemical handling and waste disposal.

System integration includes instrumentation and control devices (instruments, flow meters, pressure gauges, etc.), control logic and programming, and commissioning and start-up. All of our wastewater treatment plants are fully automated with full reach-back capabilities to our headquarters. Water treatment devices can be managed locally using user-friendly programming and color touch screens or our staff can monitor and manage water treatment devices remotely.

Return on Investment - Our distributed water management strategy brings a turnkey suite of services to the point of production. Benefits derived from our Lifecycle Water Management Services and 100% Recycle/Reuse Model are significant across the life of fields, basins, and mines:

|

- Provides an overall water management plan

|

- Reduces producer time spent on water management

|

- Lowers operation & maintenance costs in the field

|

- Reduces water acquisition & hauling costs

|

- Promotes recycling and beneficial uses of treated wastewater

|

- Reduces environmental & regulatory risks

|

- Promotes good stewardship of natural resources and

|

- Significantly Increase returns on investment.

|

|

Bench Scale Testing Services

(Download Service Brief)

Wastewater Resources Inc. has launched a new service to the Coal, Oil & Gas (COG) Industry - Bench Scale Testing Services. Knowing the concentration of the chemicals of concern (COCs) in wastewater generated by drilling and completion operations is the first step in managing environmental risks at a wellsite. Bench scale testing is the second step.

Our "bench test" services are for wastewater samples from drilling, completion, and production operations for crude oil, natural gas, and coalbed methane (CBM):

|

drilling fluids

|

|

frac flowback and

|

|

produced water.

|

The bench scale test is an inexpensive solution for evaluating the treatability well-specific wastewater using our pretreatment or advanced treatment technologies to effectively treat your wastewater. Testing well-specific water samples in our laboratory is the most cost-effective method of ensuring the maximum success of our treatment technologies in the field.

|

|

A Bench Test is sometimes called a treatability test and offers many benefits:

|

Creates site-specific conditions in a controlled laboratory setting

|

|

Aids in the proper design of devices in the treatment train

|

|

Improves design efficiency of a custom treatment train

|

|

Verifies successful results prior to deployment to field or mines

|

|

Establishes preliminary costs of chemical and power consumption

|

|

Ensures recycling, reuse and/or regulatory specifications are met and

|

|

Establishes the lowest possible cost of the wastewater treatment plant.

|

|

|

|

|

|

|

|

Our state-of-the-art product lines convert well and mining wastewaters from waste byproducts to a natural resource.

AquaTex™ COG reclaims, cleans, and recycles drilling fluids, frac flowback and produced water .

|

|

|

It also reclaims, cleans, and recycles acid mine drainage and other mining wastewater.

|

|

|

| AquaTex™ COG uses multistage flocculation-separation-filtration processes to remove TSS from wastewaters. |

|

|

AquaTex™ COG Advanced combines pretreatment and advanced treatment to remove TSS and TDS from wastewaters.

AquaTex™COG Advanced also polishes treated wastewater for beneficial use for agriculture, ranching, industry & recreation.

All of our wastewater treatment plants for the Minerals & Mining Market our fully automated for local and remote monitoring and management.

Fracking a well uses around four million gallons or 1,000 truckloads of freshwater, and generates around 1.4 million gallons or 350 truckloads of flowback recovered for treatment prior to recycling, reuse, or disposal.

Water management costs can exceed $750,000 or more to drill and complete a horizontal well.

Deploying our COG treatment plants can reduce total water management costs by up to 40% by recycling treated wastewaters in the field or at the mine. |

|

|

| WRI has teamed up with Black & Veatch to provide Life Cycle Water Management Services to the Minerals & Mining Market. |

|

| Our team offers a turnkey suite of water management services so oil and gas producers and mining operators can focus on delivering vital product to the marketplace. |

|

| Our 100% Recycle/Reuse Model advocated the continuous reclamation, treatment and recycling of treated wastewaters to drive costs down over the life of oil & gas fields and mines. |

|

| The distributed feature of Lifecycle Water Management brings wastewater treatment to fields and basins. |

|

| Each trailer-mounted plant treats 3,500 barrels of reclaimed wastewater daily. |

|

Our central water plants treat up to 15,000 barrels of reclaimed wastewater daily.

By distributing treatment plants in the fields and basins to recycle treated wastewater, costly water and wastewater hauling costs are substantially reduced or eliminated.

|

|

Under lifecycle water service agreements, we design, build, operate and maintain your wastewater treatment plants and facilities.

|

All of our treatment systems are equipped with automated controls for onsite and remote monitoring and management.

|

|

By integrating water and wastewater equipment and services, oil, gas, and mining companies can substantially improve their returns on investment.

|

Knowing the chemicals of concern (COCs) in well wastewater is the first step in reducing environmental risks.

The Bench Test is the second step in effectively removing COCs from well wastewater.

Our Bench Test Services evaluate the treatment of wastewater samples under laboratory conditions.

We test shipped samples of drilling fluids, flowback and produced water in our lab.

The purpose of bench testing is to optimize treatment conditions and devices in a laboratory setting before deploying the treatment plant to the field.

|

A Bench Test offers many benefits that ultimately reduce treatment costs while improving the effectiveness of treatment to meet regulatory limits or specifications. |

|

|